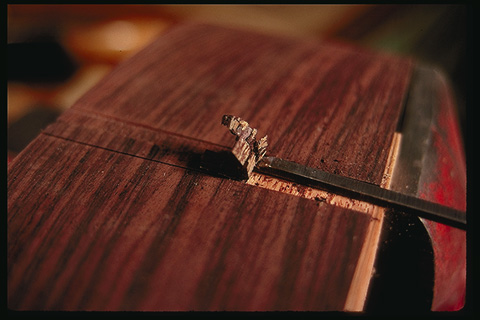

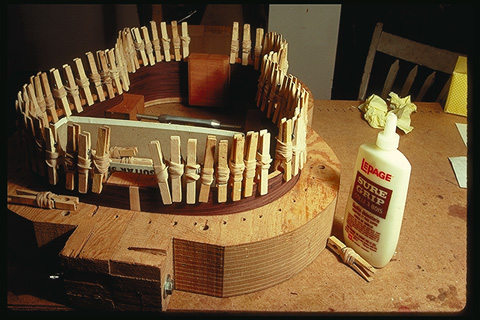

The sides are trimmed to create space for an inlay at the tail of the

instrument.

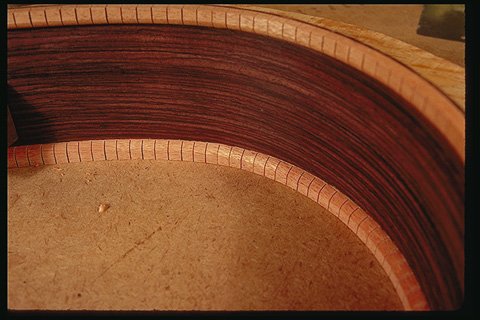

The type of inlay varies for steel and classical guitars, with the later

typically being more complex.

At the heel block, a dovetail mortise is cut into the sides and heel block